The Importance of Weld Mesh Rolls and Their Suppliers

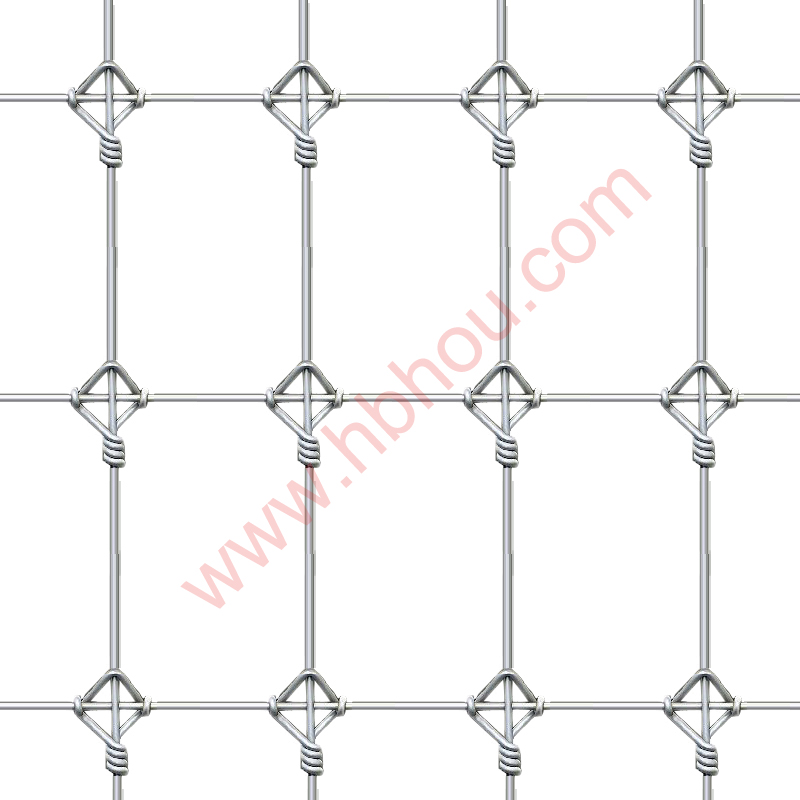

Weld mesh rolls have become an essential product in various industries due to their versatility, strength, and durability. These rolls are made of intertwined wires that are welded together at their intersections to create a grid-like pattern. Traditionally used in construction, agriculture, and manufacturing, weld mesh rolls provide robust solutions for structural support, security fencing, and animal enclosures.

Applications of Weld Mesh Rolls

Weld mesh rolls are widely used in different applications. In the construction industry, they are utilized as reinforcement for concrete slabs, walls, and floors, significantly enhancing the load-bearing capacity of structures. The mesh allows for proper distribution of weight, providing additional strength and ensuring long-lasting durability.

In agriculture, weld mesh rolls serve various purposes, including fencing for livestock, garden protection, and crop support. They help keep animals in designated areas while preventing pests from invading crops. Additionally, the rolls can be shaped into tunnels for plant support, allowing vines and climbers to thrive.

The manufacturing sector also benefits from weld mesh rolls. They can be used to create safety barriers, storage cages, and material handling equipment. Their ability to withstand heavy loads and resist corrosion makes them ideal for industrial applications where strength and resilience are paramount.

Selecting Quality Suppliers

Choosing the right supplier for weld mesh rolls is crucial to ensure quality and reliability. When sourcing these products, consider suppliers that offer a diverse range of mesh sizes, wire diameters, and coatings. A reputable supplier should provide detailed specifications, allowing customers to select the best option for their specific needs.

weld mesh rolls suppliers

Quality assurance is another critical factor. Suppliers should adhere to industry standards and regulations, ensuring that their products are manufactured with high-grade materials. Establishing a solid relationship with a dependable supplier can lead to consistent quality, timely deliveries, and better pricing.

It is also advisable to look for suppliers that prioritize customer service. Responsive communication and support can make a significant difference in addressing any concerns or queries. A supplier who understands your business needs and can provide tailored solutions will help you achieve your goals more effectively.

Innovations in Weld Mesh Production

As industries evolve, so does the production of weld mesh rolls. Innovations in technology have led to the development of new materials and manufacturing processes. For example, galvanized and stainless-steel options are now available, offering additional resistance to rust and corrosion. This is particularly beneficial for applications in harsh environments or industries where sanitation is crucial, such as food production.

Furthermore, advancements in automated welding processes have improved production efficiency, allowing suppliers to offer competitively priced products without compromising quality. Sustainable practices are also gaining traction, with suppliers exploring eco-friendly materials and methods to reduce their carbon footprint.

Conclusion

Weld mesh rolls are invaluable in various industries, providing strength, versatility, and durability for numerous applications. When sourcing these products, it is vital to choose reputable suppliers that offer quality assurance, diverse options, and excellent customer service. Innovations in production techniques and materials continue to enhance the offerings available, ensuring that weld mesh rolls remain a reliable choice for future projects. By investing in top-quality weld mesh rolls, businesses can enhance their operational efficiency, safety, and overall performance in their respective fields.