The Importance of Welded Mesh Suppliers in Industrial Applications

Welded mesh is a versatile and essential product used across various industries, including construction, agriculture, and fencing. The reliability of welded mesh largely depends on the quality of the manufacturing process and the materials used, which is where welded mesh suppliers play a crucial role. This article will explore the importance of choosing the right welded mesh supplier and the characteristics that define a top-notch provider.

What is Welded Mesh?

Welded mesh is constructed from steel wires that are welded together at their intersections, creating a robust and stable grid-like structure. The mesh can come in various shapes, sizes, and wire gauges, making it suitable for a wide array of applications. Its primary advantages include high tensile strength, resistance to deformation, and durability, making it an ideal choice for construction reinforcement, livestock enclosures, and security fencing.

Factors to Consider When Choosing Welded Mesh Suppliers

1. Quality of Materials The foundation of any reliable welded mesh product lies in the quality of the raw materials used. A reputable supplier should utilize high-grade steel that is resistant to corrosion and rust. Look for suppliers who purchase their materials from trusted manufacturers, ensuring that they meet the necessary industry standards.

2. Manufacturing Process The production process of welded mesh can significantly affect its performance. Superior suppliers use advanced technology and machinery to ensure precision in welding and cutting. It is essential to choose suppliers who adhere to strict quality control measures throughout the manufacturing process.

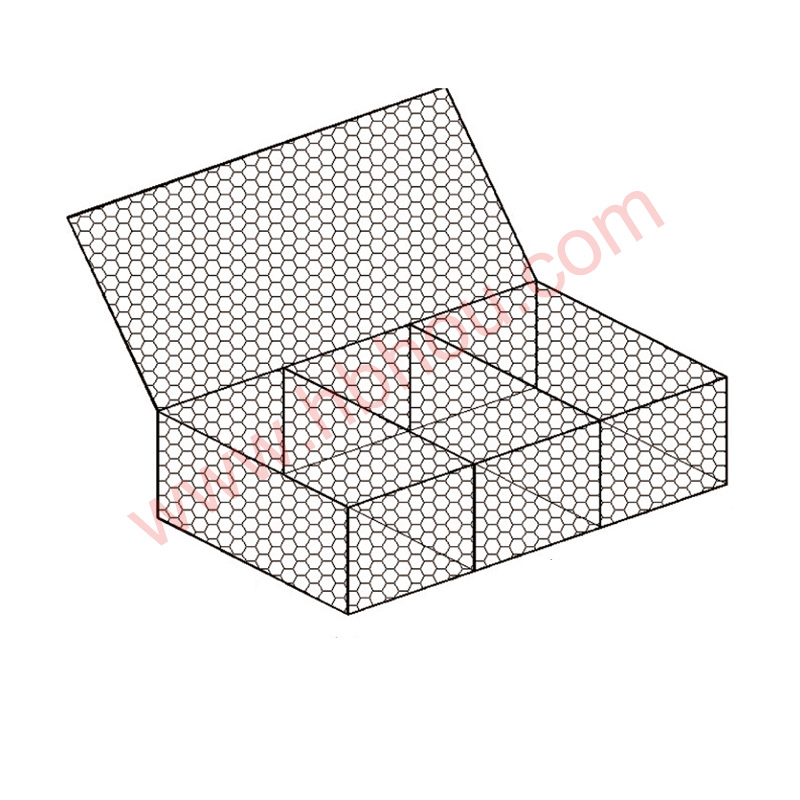

welded mesh suppliers

3. Product Range A versatile supplier will offer a variety of welded mesh products in different sizes and specifications. This ensures that clients can find exactly what they need for their specific projects. Whether it’s for structural reinforcement in buildings or agricultural fencing, a well-stocked supplier can meet diverse requirements.

4. Custom Solutions In many cases, businesses may require customized solutions to address unique challenges. Top suppliers offer tailored products based on the specifications provided by the client, taking into account factors like wire diameter, mesh spacing, and coating options.

5. Experience and Reputation The track record of a welded mesh supplier speaks volumes about their reliability. Suppliers with years of experience in the industry are more likely to understand and address the needs of their clients effectively. Reading customer reviews and testimonials can also provide insight into the company’s reputation.

6. Customer Service A good supplier prioritizes customer satisfaction. This includes clear communication, timely responses to inquiries, and support during the ordering process. Establishing a solid relationship with a supplier can streamline future transactions and lead to better pricing and service.

7. Delivery and Logistics Timely delivery is crucial in maintaining project schedules. Reputable suppliers have efficient logistics in place to ensure that orders are dispatched promptly and safely. This reliability helps in avoiding unnecessary delays in construction or production activities.

Conclusion

Choosing the right welded mesh supplier is a critical decision that can impact the overall success of a project. By focusing on factors such as material quality, manufacturing processes, product range, and customer service, businesses can ensure that they partner with a reliable supplier. Ultimately, the right supplier not only provides quality products but also contributes to the long-term success and sustainability of projects across various industries. In a world where precision and reliability are paramount, welded mesh suppliers are key players in ensuring that the foundations of our infrastructures are strong and secure.