The Importance of Soldering Iron Cleaning Wire in Electronics

When it comes to soldering in the electronics field, one of the most essential tools in a technician's arsenal is the soldering iron. However, even the best soldering iron can produce less-than-ideal results if not properly maintained. A key aspect of maintaining a soldering iron is ensuring that the tip is clean and free of oxidation and solder residue. This is where soldering iron cleaning wire comes into play.

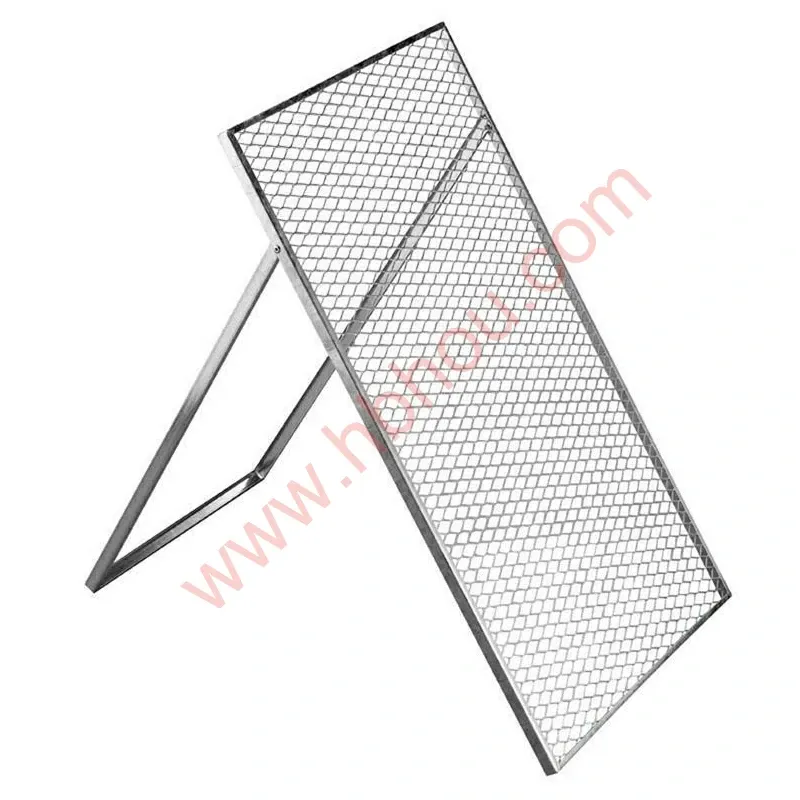

Soldering iron cleaning wire, often referred to as brass wire or soldering tip cleaning wire, is a cleaning medium made from fine brass strands. Unlike traditional sponges or damp rags, which can introduce moisture to the soldering iron's tip, cleaning wire provides a dry method for effective cleaning. This is crucial because moisture can lead to oxidation, which degrades the soldering iron’s performance over time.

The primary function of soldering iron cleaning wire is to remove excess solder, oxidation, and debris from the tip. When a soldering iron is heated and used to solder components on a circuit board, solder can accumulate on the tip. A clean tip is essential for optimal heat transfer and solder flow, ensuring that joints are strong, reliable, and free of cold solder joints. Dirty tips can lead to poor solder connections, which can result in malfunctioning devices and ultimately compromise the integrity of the entire project.

soldering iron cleaning wire

Using soldering iron cleaning wire is straightforward. Simply touch the hot soldering iron tip to the brass wire for a moment, and the wire will remove any oxidation and solder build-up. This method of cleaning not only restores the tip to better working conditions but also prolongs its life by minimizing the wear and tear caused by harsher cleaning methods. As a bonus, cleaning with brass wire is quick and efficient, allowing technicians to maintain their workflow without significant interruptions.

Another advantage of using soldering iron cleaning wire is that it is reusable and doesn’t carry the risks associated with other cleaning methods. For example, sponges or cloths can harbor contaminants or fibers that could get stuck on the soldering iron tip, compromising the quality of the solder joint. Brass wire, on the other hand, is free from such issues and can effectively clean the tip without leaving any residues behind.

In addition to its practical benefits, using soldering iron cleaning wire can lead to a more professional finish. When technicians maintain clean tips, they are more likely to achieve better solder joints, leading to a higher-quality final product. This attention to detail is imperative in the competitive field of electronics, where precision and reliability are paramount.

In conclusion, soldering iron cleaning wire is an invaluable tool for anyone working with soldering irons in electronics. It enhances the performance of soldering tips, improves the quality of solder joints, and extends the lifespan of soldering equipment. By adopting this simple yet effective cleaning method, technicians can ensure that they achieve the best results in their work, leading to successful projects and satisfied clients. Investing in a good quality soldering iron cleaning wire is not just an option; it's a necessity for any serious soldering technician.