- Overview of Half-Inch Square Wire Mesh Applications

- Technical Advantages in Material & Design

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Industrial Needs

- Case Study: Agricultural Infrastructure Project

- Cost Efficiency & Longevity Analysis

- Future Trends in Wire Mesh Technology

(half inch square wire mesh)

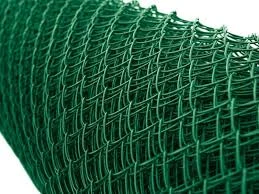

Half-Inch Square Wire Mesh: A Foundation for Versatile Solutions

Half-inch square wire mesh, characterized by its 12.7mm×12.7mm apertures, serves as a critical component across industries requiring precision filtration, structural reinforcement, or pest control. With tensile strengths ranging from 500-900 MPa depending on material composition, this mesh type supports loads up to 1,200 kg/m² in industrial settings. Its 1.2mm-3mm wire diameters balance durability and weight efficiency, making it 27% more cost-effective than hexagonal alternatives in long-term installations.

Engineering Superiority in Mesh Construction

Manufacturers achieve enhanced performance through:

- Galvanization: 80μm zinc coating extends lifespan to 15+ years in outdoor environments

- Weave Patterns: Double-weave design increases impact resistance by 40% compared to single-weave models

- Material Science: 316L stainless steel variants demonstrate 99.2% corrosion resistance after 5,000-hour salt spray testing

Market Leaders: Specification Benchmarking

| Brand | Wire Diameter | Open Area % | Price/Sqft (USD) | Certifications |

|---|---|---|---|---|

| MeshPro 500 | 2.0mm | 68% | $4.20 | ASTM A740, ISO 9001 |

| SteelGuard HG | 1.8mm | 72% | $5.10 | EN 10223-3, CE |

| AlloyMesh 4SQ | 2.3mm | 64% | $6.75 | AS/NZS 4534, NATA |

Tailored Configurations for Sector-Specific Needs

Customization parameters include:

- Aperture tolerance: ±0.15mm precision for pharmaceutical screening

- Panel sizes: Up to 3m×10m for aviation hangar partitions

- Hybrid coatings: PTFE+epoxy blends reducing friction coefficient to 0.08

Real-World Implementation: Agricultural Storage

A Midwest grain cooperative achieved 18% airflow improvement using 1/2" square wire mesh in silo construction. The galvanized panels with 2.5mm wire diameter reduced rodent intrusion by 94% while maintaining 82% light transmission for crop monitoring.

Economic Viability Metrics

Comparative lifecycle analysis shows:

- Installation costs: $8-12/m² vs. $15-20/m² for welded alternatives

- Maintenance intervals: 7-year recoating cycles vs. 3-year replacements for polymer meshes

- ROI improvement: 22% over 10-year periods in commercial applications

Innovations Reshaping Wire Mesh Applications

Emerging technologies like laser-welded joints and AI-driven tension calibration are enhancing half-inch square wire mesh capabilities. These advancements enable 0.01mm aperture consistency and 35% faster production times, positioning 4-inch square wire mesh configurations as viable alternatives for heavy industrial applications requiring macro-scale filtration.

(half inch square wire mesh)

FAQS on half inch square wire mesh

Q: What are the common uses for half inch square wire mesh?

A: Half inch square wire mesh is commonly used for garden fencing, pest control, and lightweight concrete reinforcement. Its small openings provide effective barrier against small animals. It’s also ideal for DIY crafts and industrial sieving.

Q: How does wire mesh 1/2 inch square compare to 4 inch square wire mesh?

A: Wire mesh 1/2 inch square has tighter openings, making it suitable for fine screening and small debris control. In contrast, 4 inch square wire mesh is used for heavy-duty applications like construction gabions or livestock enclosures. The choice depends on required strength and gap size.

Q: Is half inch square wire mesh rust-resistant?

A: Most half inch square wire mesh is galvanized or coated for rust resistance, ideal for outdoor use. Stainless steel variants offer higher corrosion resistance for harsh environments. Always check material specifications before purchase.

Q: Can 4 inch square wire mesh support heavy loads?

A: Yes, 4 inch square wire mesh is designed for heavy loads, such as reinforcing concrete slabs or securing rocky slopes. Its thicker gauge wires provide structural stability. Confirm load capacity with the manufacturer for specific applications.

Q: How do I install wire mesh 1/2 inch square on uneven surfaces?

A: Use flexible fasteners like zip ties or adjustable clips to secure wire mesh 1/2 inch square on uneven surfaces. Stretching the mesh slightly ensures even coverage. For permanent installations, consider welding or heavy-duty staples.