The Current Trends in Galvanized Iron Wire Pricing

Galvanized iron wire, known for its durability, corrosion resistance, and versatility, plays a pivotal role in numerous industries ranging from construction to agriculture. As demand for this essential material fluctuates, understanding the factors influencing its pricing becomes increasingly important for businesses and consumers alike.

One of the primary reasons for the price variations in galvanized iron wire is the cost of raw materials, particularly iron ore and zinc. These materials are subject to global market dynamics, which means that the prices can change based on mining outputs, geopolitical tensions, and trade policies. For instance, recent supply chain disruptions caused by geopolitical conflicts have led to fear of shortages, driving prices up. In contrast, periods of economic slowdown can lead to decreased demand, prompting suppliers to reduce their prices to stimulate sales.

Another significant factor affecting galvanized iron wire prices is the manufacturing process. The process involves coating iron wire with a layer of zinc through either hot-dip galvanizing or electro-galvanizing. Each method varies in cost-effectiveness, influencing the final price of the product. For example, hot-dip galvanizing is generally more expensive due to its higher material and labor costs. Manufacturers must balance these costs while remaining competitive in the market, which can lead to fluctuations in pricing strategies.

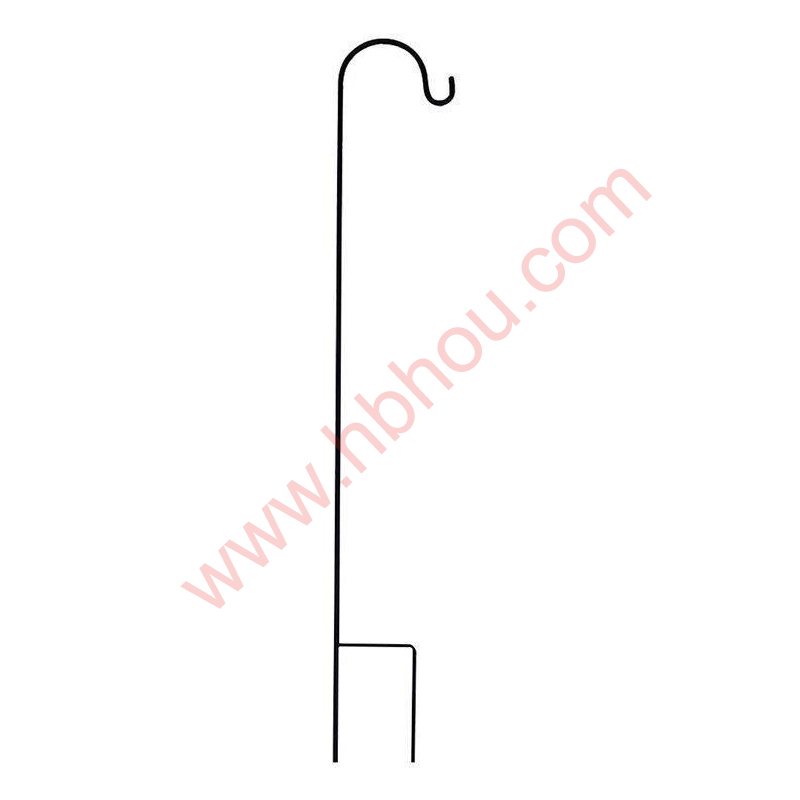

galvanized iron wire price

Market demand also plays a crucial role in determining galvanized iron wire prices. The construction sector, for example, relies heavily on this material for fencing, barbed wire, and various structural applications. When the construction industry experiences growth, the demand for galvanized iron wire rises, potentially pushing prices higher. Conversely, during economic downturns, demand can plummet, resulting in lower prices. Similarly, sectors like agricultural fencing and crafting also influence demand, with seasonal trends leading to price variability throughout the year.

Additionally, advancements in technology and production methods can impact prices. New manufacturing techniques that improve efficiency or reduce waste can lower production costs, which may, in turn, lead to more competitive pricing for consumers. Companies investing in innovative processes often find themselves at an advantage, allowing them to maintain better price stability even during market fluctuations.

Environmental regulations are becoming increasingly influential in the pricing of galvanized iron wire. Stricter standards regarding emissions and waste management can raise operational costs for manufacturers, which may be passed on to consumers in the form of higher prices. Conversely, companies that adopt green practices may enjoy a better market position, appealing to environmentally conscious buyers.

In summary, the price of galvanized iron wire is shaped by a multitude of factors, including raw material costs, manufacturing methods, market demand, technological advancements, and environmental regulations. Businesses and consumers must remain vigilant and informed about these dynamics to make optimal purchasing decisions. As global economic conditions continue to evolve, staying updated on the trends influencing galvanized iron wire pricing is essential for anyone looking to engage in this market. Whether for construction, agriculture, or crafting, understanding these elements can lead to informed choices and better financial outcomes.